PTFE Nano Mask Membrane

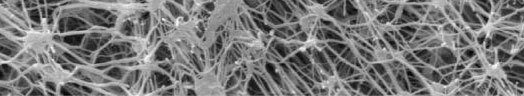

PTFE nanomembrane The PTFE membrane prepared by the unidirectional or biaxial stretching method has a spider web-like microporous structure on the surface, and has very complex changes in the three-dimensional structure, such as network connection, hole inlay, and pore bending, so it has excellent surface filtering function. The nano-mask produced by this material has the characteristics of high barrier efficiency, long service life, light, thin and breathable.

Technical indicators

| ITEMS | Measured value | Parameter |

| Width | ≤1600mm | |

| Salt flration eficiency95L/min | ≥99% | GB/T 32610-2016 |

| Oil fltration eficiency95L/min | ≥95% | GB/T 32610-2016 |

| Bacterial fitration efficiency(BFE) | 99.7 | YY 0469-2011 |

| Inspiratory resistance | ≤85 | GB/T 32610-2016 |

| Exhalation resistance | ≤100 | GB/T 32610-2016 |

Product comparison

| PTFE Nano mask film | Meltblown PP non-woven fabric | |

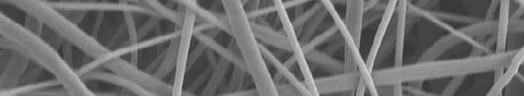

electron microscope picture |  |  |

| Structure | Fiber diameter0.1-0.2um(100 -200Nano),Ultra-fine fiber, complex pore structure, can provide absolute filtration accuracy, large total adsorption area and high filtration efficiency. | The average fiber diameter is 2um, the relative pore size is large, the total adsorption area is small, and the filtration efficiency is low. |

| applicability | The PTFE membrane is naturally hydrophobic, and the filtration mechanism is physical and mechanical interception (pore size interception method), which will not reduce the interception rate due to moisture in the exhaled breath. Compared with ordinary meltblown cloth masks, the electrostatic adsorption protection effect is more stable and lasting. | The average fiber diameter is 2um, the relative pore size is large, the total adsorption area is small, and the filtration efficiency is low. |

| comfort | The PTFE membrane is through the overall stretching process, will not fall off the fiber, and has an ultra-thin thickness, the thickness is less than 5 microns, the total thickness of the composite non-woven fabric is less than 100um, and it is more comfortable to wear. | The thickness of the melt-blown non-woven fabric is about 150 microns, and the thickness is higher, and the melt-blown film is relatively fragile and easy to fall off fibers. |

Application field

PTFE nanomembrane is used for protective equipment such as masks, which can intercept various bacteria and particles, and can obtain a high interception efficiency of 99-99.5 under lower resistance. KN95 masks; medical protective masks; ordinary masks.

Keyword:

PTFE Nano Mask Membrane

Leave A Message

Contact us for more preferential prices